Distillation columns are used in small scale laboratories as well as in big manufacturing types of industries such as General Chemical Production,Petrochemicals and Renewable Fuels. Distillation is a separation technique that utilizes differences in boiling points between two or more chemical substances in their liquid phase.

For example, water boils at 100°C at atmospheric pressure, or 1 Bar. At 0.1 Bar, it boils at 50°C. In this example, water has a vapor pressure of 1Bar at 100°C and 0.1 Bar at 50°C. Ethanol, as another example, has a vapor pressure of 2.2Bar at 100°C and 0.31 Bar at 50°C.

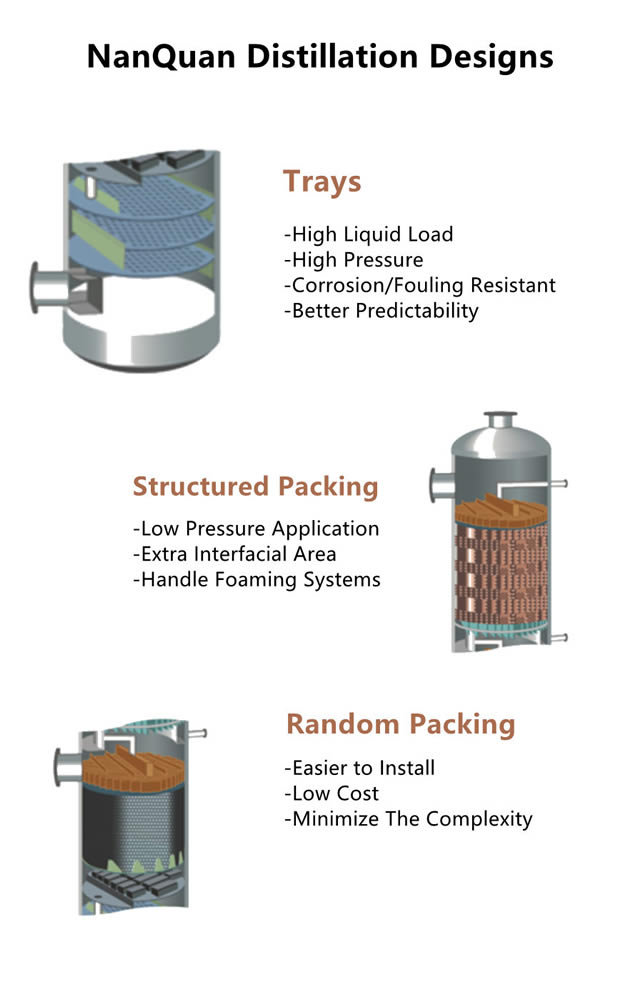

Since the vapor pressure of ethanol is higher than water, it is more volatile. There are two main column options for a distillation system: trayed columns and packed columns, which differ in their shape, reliability, and ability to withstand pressure.

Specification

Materials

Optional Features

A variety of internal and external material and weld finishes are available

Externals and structural steel of carbon steel finish painted

Body flange vessel connection

Internals—bed Limiter, packing support plates and packings, liquid collector, liquid distributor, and more

Down comers—bolt on or welded in place

Additional nozzles as required

Insulation and welded outer sheathing

Distillation Process

Trays